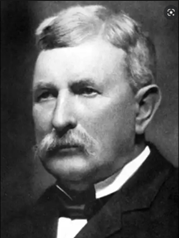

Benjamin Holt was born in Concord, New Hampshire in 1849 and was the youngest of four brothers. Having been born to a hard-working blue-collar father who owned a sawmill making hardwood for wagon coaches, entrepreneurship and industriousness came natural to Benjamin at a young age. In the late 1800’s, Benjamin would find himself in California where he and his brothers would form the Stockton Wheel Company where Benjamin would design and patent new ways to move supplies and material throughout the Western United States. His patents for tractor engines and track treads would eventually lead to the creation of Caterpillar Inc. in 1925.

Prior to the 1900’s, there were many attempts by individuals to construct machines that would move on crawler or track-like treads with little success. 1 Benjamin’s invention of the steam engine and his ability to successfully operationalize track treads revolutionized mobile mechanization in ways that have led to improvements in economic growth and development throughout the United States and abroad.

Although Benjamin sought efficiencies and improvements in the use of agricultural logistics, his inventions had far-reaching implications and it was not long until his patent for track treads would see use in World War I and his tractors would see heavy use across the battlefields of Europe in lieu of horses.

While exploring new markets for the Caterpillar, in November 1913 Benjamin wrote a letter to then Senator Miles Poindexter, Chairman of the Senate Committee on Expenditures in the War Department explaining to Mr. Poindexter how Holt Manufacturing Company “has a special type of Caterpillar equipped with a two-speed transmission which will enable the War Department to reduce its horse flesh in time of war, very materially. We have already shipped some of these machines to foreign lands and we are meeting with more or less success in interesting various War Departments in Europe in this type of Caterpillar.”[i] It was not until 1915 with the War Department decided to test the Caterpillar’s at the Rock Island Arsenal in Illinois. As a result and according to The California Agriculture Museum, “in November 1918, a total of 676 Holt 120 Crawler tractors were made for the war effort at a cost of about $6875 each. They represent early track-type tractors with a front tiller wheel and they were designed to outlast and replace horses that were vulnerable to gun fire, exhaustion, and famine.” 2

By 1909, the Holt Manufacturing Company purchased failing implement maker Colean Manufacturing Company and the two merged to become the Holt Caterpillar Company and soon after Benjamin had Caterpillar trademarked. The post-World War I economy was on the brink of the Great Depression which resulted in decreasing sales of Benjamin’s tractors. Due mostly in part to cancelled military contracts and heavy investments in R&D that resulted in little to no return on investment for Benjamin at the close of the war in 1918. 3

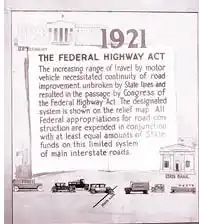

By this time, Benjamin shifted his focus from developing predominately agricultural machinery to machinery that would be used to facilitate and help with the construction of America’s growing network of roads which would prove vital in America’s continued western expansion with the proposal of the Federal Highway Act which would not be signed into law until November 9, 1921. Unfortunately, Benjamin would not live to see his Caterpillars put to work on the vast network of road development.

Benjamin died on December 5, 1920 of an unknown illness and five years later his Holt Caterpillar Company would merge with C.L. Best to form what is known Caterpillar Inc. The post-war economy after World War I would find itself on the cusp of the Great Depression lasting until 1929. During these turbulent economical times and dwindling demand for Caterpillar’s within the United States, Caterpillar stayed afloat by exporting its products overseas which consisted of roughly half of their sales. In comparison, the automotive industry was gaining traction with the production of Henry Ford’s Model T and Model A automobiles. Driven by demand, production for the Model A increased from 108,127 Model A’s in 1928 to 216,626 Model A’s by 1929. 4 The average cost for a consumer to purchase a Model A in 1929 was $500 which would suggest an annual estimated gross revenue of $108,313,000 for Ford’s Model A in 1929 which is double compared to reported Caterpillar sales of $52 million in 1929.[i]5 Despite economic conditions of the time, we also must consider the variables included in these differing production cycles such as time, materials, labor, manning and cost of goods, etc. However, today Caterpillar Inc. has grown to become a multi-billion-dollar industry and its sphere of influence is global. Having been founded almost 100 years ago, Caterpillar Inc. continues to “break ground” for all types of industries employing its use.

4 Motortrend. “Model A Coupes – Heir to the Throne. Last Modified February 11, 2011. https://www.motortrend.com/features/1102sr-model-a-coupes/.

2 ibid.

1 Wik, Reynold. “Benjamin Holt and the Invention of the Track-Type Tractor.” Technology and Culture. Jan. 1979, Vol 20, No 1 (Jan. 1979), pp 90-107. The John Hopkins University Press and the Society for the History of Technology. https://www.jstor.com/stable/3103113.